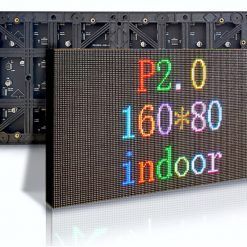

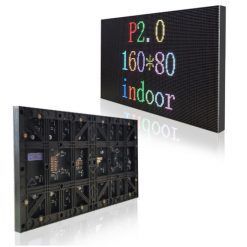

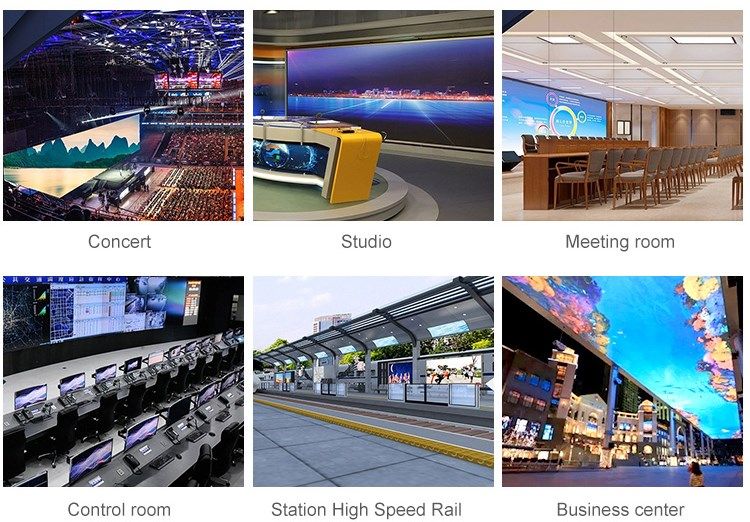

indoor LED panel screen full color P2 LED digital display

P2 Indoor led display module, SMD1515 full color led video advertising walls, with Novastar control cards and Nationstar leds, Meanwell power supply for indoor fixed led displays.

indoor LED panel screen full color P2 LED digital display

LED module is an important part of the P2 LED display panel, if the LED module has a problem, it will directly affect the P2 LED display screen quality! Therefore, how to identify the quality of the LED module is very important, the following is a common method for LED display manufacturers to judge the quality. When you purchase a P2 led display, you can also consider it!

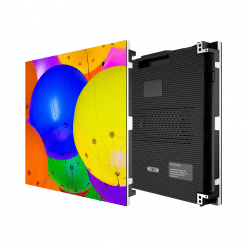

1. P2 LED display panel

Some P2 LED display manufacturers use low-cost flame-retardant paper boards or single-sided fiberboards as the LED circuit board for low-price competition. Because all fiberglass PCB board is expensive. The difference cannot be seen at the beginning. Under normal circumstances, it will break due to moisture, UV damage, oxidation, etc. in one year, resulting in the scrapping of the entire LED cell board. High-quality LED displays must use double-sided glass fiber PCBs, which are cost-effective but guaranteed.

2. Lamp beads and chips:

The naked eye can’t tell whether the lamp is good or bad. Can only rely on long-term tests, that is, experts say aging test. The general full-color LED display manufacturer’s approach is: power before leaving the factory, check whether the LED display can work normally, it will not go through a long time aging test. Because there are time costs and labor costs.

3. IC device

Observe the consistency of the brand of IC device used. What type of IC, and how many ICs are used, are also enough to affect the quality of the P2 LED display. Some LED display manufacturers, in order to save costs, will deliberately reduce the number of ICs when manufacturing cell boards, or intermingle with other brands of ICs.